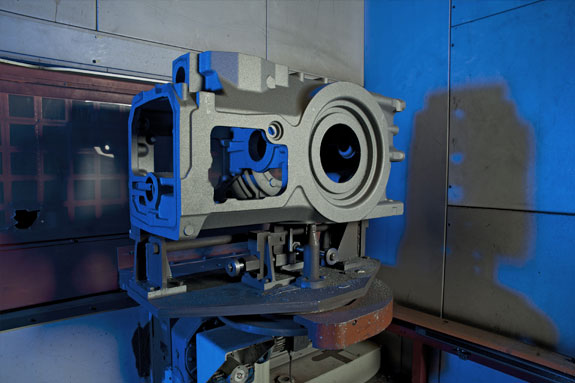

Moulding lines

One moulding line , « Osborn-Savelli », with a capacity of 70 moulds an hour.

Osborn – Savelli : 1300 x 800 x (2 x 380)

Melting

2 furnaces, induction frequency, producing a capacity of 17

tons per hour.

Converter for speroidal graphite cast iron.

A furnace with automatic pouring capabilities.

Cold Core Workshop

10 machines, Cold Core boxes, from 20 litres up to 200 litres, with robotised “ILOT”.

Finishing lines

9 manual grinding stations.

2 automatic grinding centres with dimensional control by

laser.

1 paint line using total immersion and/or spraying by hand.

Production flow

Production Flow : Core-making, Fusion, Moulding, Grinding and

Painting in line.

Enterprise Resource Planning (ERP) : Sage X3.

Metallurgical laboratory

- - mechanical tests (tractions) on ZwickRoell Z100

- - micrograph

- - machining of specimens

- - 2 polishers (manual and automatic)

- - large saw

- - digital microscope (KEYENCE VHX)

Non-destructive testing

Ultra-Sounds carried out by COFREND 1 & 2 certified personnel